Product Description:

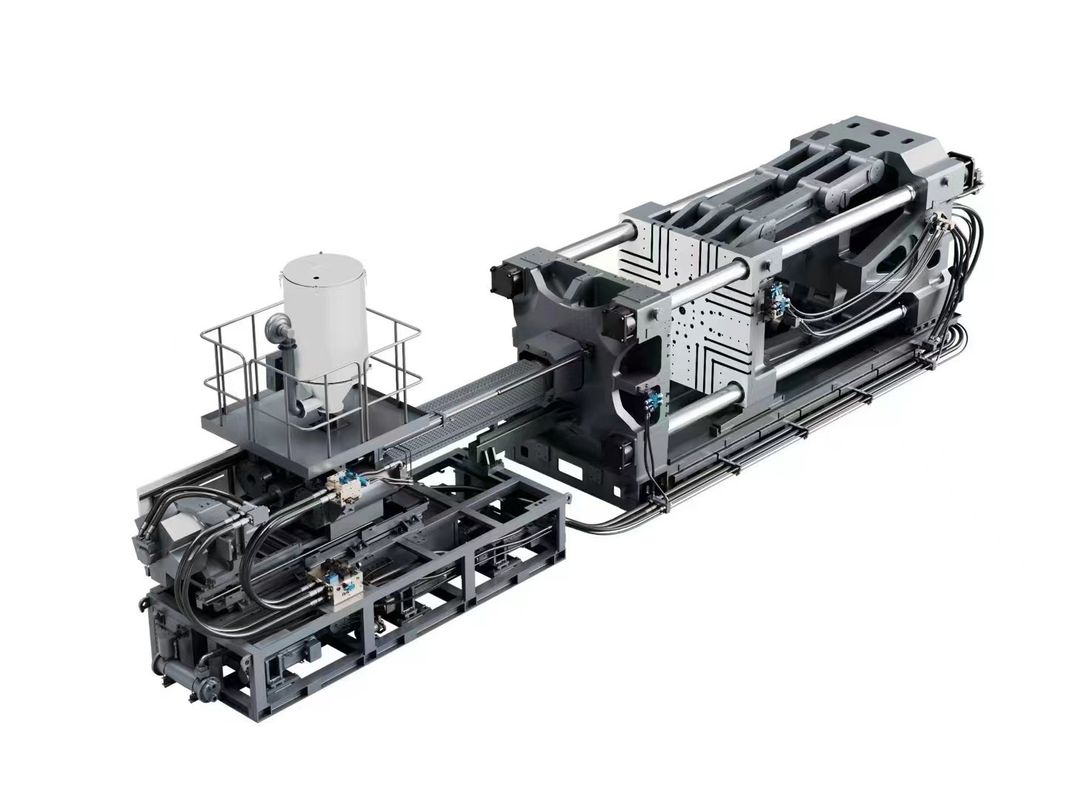

Plastic Injection Molding Machine is a type of injection moulder used for producing a wide range of plastic parts, components, and products. It is suitable for manufacturing items ranging from small components to large components, such as automotive parts, medical parts, and consumer electronic components. The Plastic Injection Molding Machine offers high performance, precision, and maximum flexibility. It features a powerful clamping force ranging from 50 to 4000 tons, injection weight from 50 to 40000 grams, max. mold height from 500 to 1500mm, clamping stroke from 200 to 1000mm, and nozzle pressure from 0 to 30MPa.

The Plastic Injector Molding Machine is designed with state-of-the-art technology to provide superior results and reliability. It is equipped with advanced features such as an automated control system, high-quality components, and an efficient injection system that helps to reduce costs and improve productivity. The machine is also easy to operate, with user-friendly controls and intuitive programming. Furthermore, the machine has robust construction and is designed to provide a long-term performance.

The Plastic Injector is a reliable and cost-effective solution for producing high-quality plastic parts. With its precise and repeatable results, high-speed operation, and low maintenance requirements, it is a great option for any plastic injection application. The Plastic Injector Molding Machine is perfect for businesses looking for an efficient and reliable way to produce plastic parts and components. It is the ideal choice for any industrial or commercial purpose.

Features:

- Integrated Quality Control: Look for a machine that incorporates built-in quality control features such as automated inspection systems, vision systems, or sensors to detect defects, dimensional variations, or cosmetic flaws in real-time. This feature helps ensure consistent part quality and reduces the need for manual inspections.

- Mold Changeover Efficiency: Consider a machine that offers quick and easy mold changeover capabilities. Look for features such as quick-release mold clamps, automated mold handling systems, or standardized mold bases. These features help minimize downtime between production runs and facilitate faster mold changeovers.

- Process Monitoring and Optimization: Select a machine that provides comprehensive process monitoring and optimization capabilities. This can include features like real-time process data collection, analysis, and control algorithms. These features enable you to fine-tune process parameters, optimize cycle times, and enhance overall productivity.

- Enhanced Safety Features: Safety is paramount in any manufacturing environment. Look for a machine that incorporates advanced safety features such as safety interlocks, light curtains, emergency stop buttons, and safety monitoring systems. These features help protect operators from potential hazards and ensure a safe working environment.

Technical Parameters:

| Parameter |

Value |

| Nozzle Retraction Force |

1-50KN |

| Nozzle Pressure |

0-30MPa |

| Injection Rate |

300-400mm/s |

| Heating Power |

2-100KW |

| Max. Mold Height |

500-1500mm |

| Injection Weight |

50-40000g |

| Voltage |

220V/380V/415V |

| Clamping Force |

50-4000T |

| Clamping Stroke |

200-1000mm |

Applications:

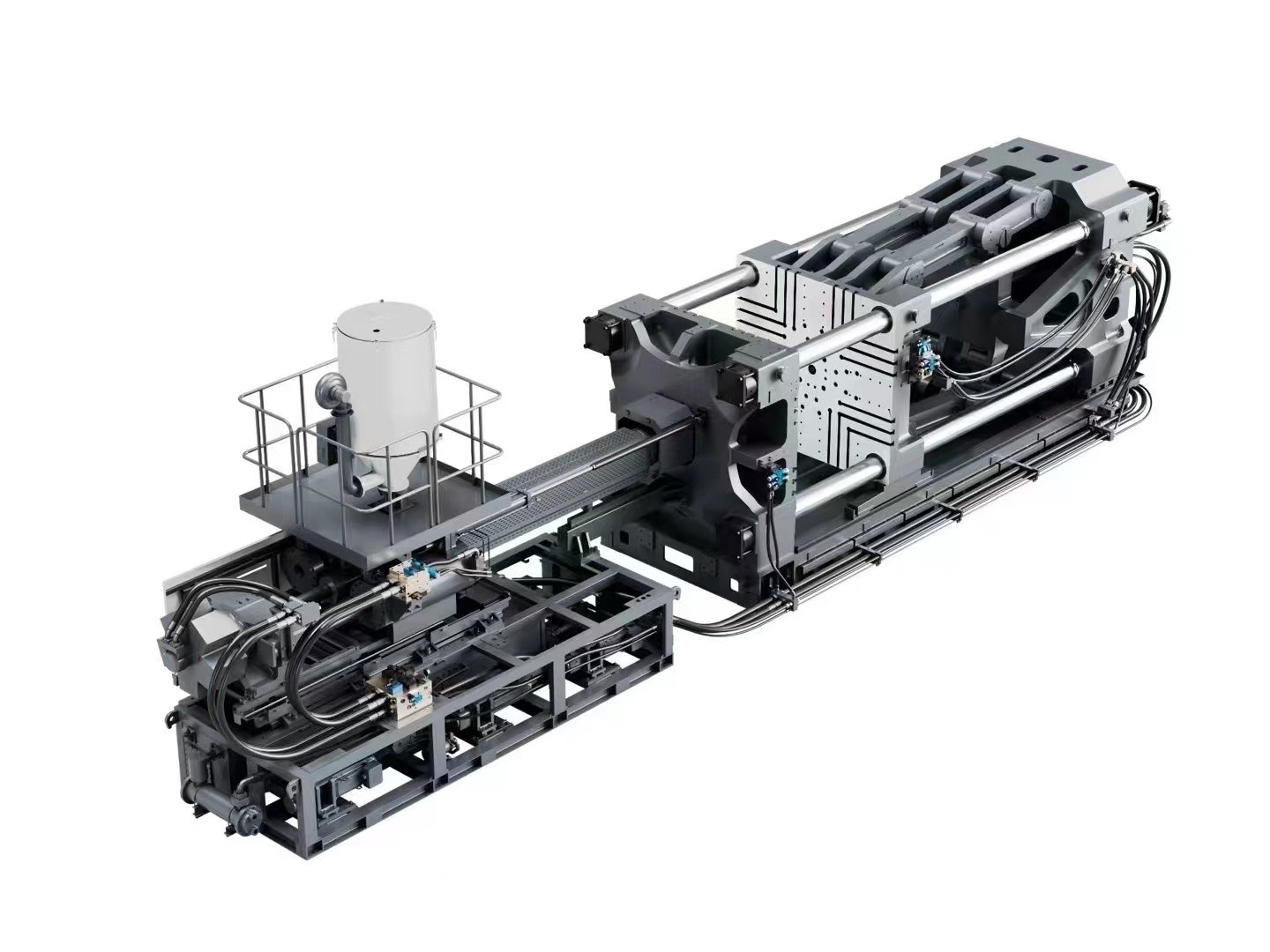

Chongyuan Plastic Injection Forming System, also known as Plastic Injection Molder Machine, is a type of plastic injection molding system certified by ISO. It is available in minimum 1 set and the price can be negotiated. The packaging details is 25kg/bag and the delivery time is 5-8 work days. It supports various payment terms such as L/C, D/A, D/P, T/T, Western Union, MoneyGram. It is made in China. It works with the voltage of 220V/380V/415V, Max. Mold Height of 500-1500mm, Nozzle Retraction Force of 1-50KN, Injection Rate of 300-400mm/s and Clamping Force of 50-4000T.

This Plastic Injection Molding System can be widely applied in various industries such as automobile, 3C electronics, home appliances, medical, aerospace and many more. It is a great choice for manufacturers, research and development institutions, and production enterprises, as it can create parts with complex structures and make them accurate. It is also suitable for mass production and can save a lot of time and costs.

Support and Services:

We provide technical support and service for Plastic Injection Molding Machine, including:

- Remote Service: Our technical team is available 24/7 to provide remote support for Plastic Injection Molding Machine.

- On-site Service: We are able to send technicians to your site to help with installation, maintenance, and repairs of Plastic Injection Molding Machine.

- Phone Support: Our customer service representatives can be reached via phone for immediate assistance.

- Warranty: We offer a comprehensive warranty on our Plastic Injection Molding Machine.

Packing and Shipping:

Plastic injection molding machines are usually shipped in wooden cases or crates to ensure they are well protected during transportation. The cases or crates are designed to fit the exact shape and size of the machines, and they are also labeled with information like product name, type, company logo, and other necessary information. The machines are also secured within the cases or crates with straps or wraps, and are often filled with foam or other cushioning material to provide extra protection.

The cases or crates can then be loaded onto trucks or other suitable vehicles for shipping. Depending on the buyer's preference, the machines may be shipped by air freight, sea freight, or by land. In some cases, buyers may also arrange for the machines to be picked up from the factory and delivered directly to the buyer's location.

FAQ:

Q: What is the Brand Name of this Plastic Injection Molding Machine?

A: The Brand Name of this Plastic Injection Molding Machine is Chongyuan.

Q: Where is this Plastic Injection Molding Machine made?

A: This Plastic Injection Molding Machine is made in China.

Q: What is the minimum order quantity for this Plastic Injection Molding Machine?

A: The minimum order quantity for this Plastic Injection Molding Machine is 1 set.

Q: What is the payment terms for this Plastic Injection Molding Machine?

A: The payment terms for this Plastic Injection Molding Machine is L/C, D/A, D/P, T/T, Western Union, MoneyGram.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!