Functional Additive Masterbatch Melting Point 120-160℃ PH Value 6-7 Density 1.2-1.4g/cm3

Product Description:

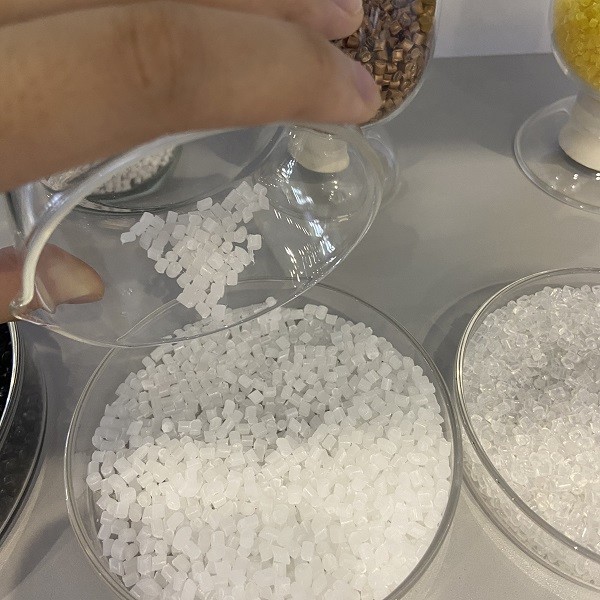

Functional Masterbatch is a performance enhancing masterbatch that is specifically engineered with a range of masterbatch additive compounds to enhance the overall performance of the finished product. It is designed to ensure the highest levels of light resistance (≥6), moisture content (≤0.2%), PH value (6-7), and density (1.2-1.4g/cm3). This functional compound masterbatch can also be customized to include various other additives such as antiblock, slip, antistatic, etc. to enhance the overall performance of the end product. Its unique blend of masterbatch additives make it an ideal choice for a wide range of industrial applications.

Features:

- Product Name: Functional Masterbatch

- Moisture Content: ≤0.2%

- Light Resistance: ≥6

- PH Value: 6-7

- Density: 1.2-1.4g/cm3

- Melting Point: 120-160℃

- Functional Compound Masterbatch

- Functional Additive Masterbatch

- Engineered Masterbatch Additive

Technical Parameters:

| Parameter |

Specification |

| Light Resistance |

≥6 |

| Melting Point |

120-160℃ |

| Moisture Content |

≤0.2% |

| Additive |

Antiblock, Slip, Antistatic, Etc. |

| Density |

1.2-1.4g/cm3 |

| PH Value |

6-7 |

Applications:

Chongyuan's Functional Polymer Masterbatch is designed to help customers achieve desired properties in their polymers and plastic products. With Model Number MBF000, this product is manufactured in Xiamen, China and features a PH value of 6-7, making it ideal for many applications. It is composed of various additives, such as antiblock, slip, antistatic, etc., and has a density of 1.2-1.4g/cm3, light resistance of ≥6, and melting point of 120-160℃. This combination of properties makes it suitable for use in a variety of industries, such as automotive, packaging, and medical. Chongyuan's Functional Polymer Masterbatch, also known as an Engineered Masterbatch Additive, provides a reliable and cost-effective solution for customers who need optimal performance in their products. Its high melting point and light resistance make it ideal for applications that require superior thermal and UV stability. The Functional Additive Masterbatch also offers excellent slip and anti-blocking properties, making it an excellent choice for applications that require superior surface quality.

Support and Services:

Technical Support and Services for Functional Masterbatch

Functional Masterbatch (FMB) is an advanced polymer additive that adds superior performance to a variety of applications. FMB can provide a range of benefits, such as improved processability, increased productivity, and better product quality. Our team of experts is committed to helping customers get the most from their FMB products.

We offer a range of technical support and services for FMB customers, including:

- Product selection and application advice

- Compatibility and stability testing

- Material compatibility assessment

- Process optimization

- Technical support and troubleshooting

- Processing guidelines and best practices

- Product training and education

We strive to provide our customers with the best possible service and technical support. Our team of experts is available to answer any questions you may have about your FMB products or applications. Please contact us for more information.

FAQ:

- Q: What is Functional Masterbatch?

A: Functional Masterbatch is a kind of concentrated additive polymers produced by Chongyuan, which model number is MBF000 and place of origin is Xiamen, China.

- Q: What advantages does Functional Masterbatch have?

A: Functional Masterbatch is a kind of concentrated additive polymers that can provide improved thermal stability, enhanced mechanical properties, improved optical properties, and improved processing.

- Q: What are the applications of Functional Masterbatch?

A: Functional Masterbatch can be used in a variety of applications such as automotive, medical, consumer products, aerospace, and packaging.

- Q: What is the difference between Functional Masterbatch and traditional Masterbatch?

A: Traditional Masterbatch is a mixture of colorants and additives, while Functional Masterbatch is a concentrated additive polymer with improved thermal stability, enhanced mechanical properties, improved optical properties, and improved processing.

- Q: What is the shelf life of Functional Masterbatch?

A: The shelf life of Functional Masterbatch is 12 months when stored in a cool, dry place.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!