Product Description:

Additive Masterbatch - A Solution for High-Quality Plastic Products

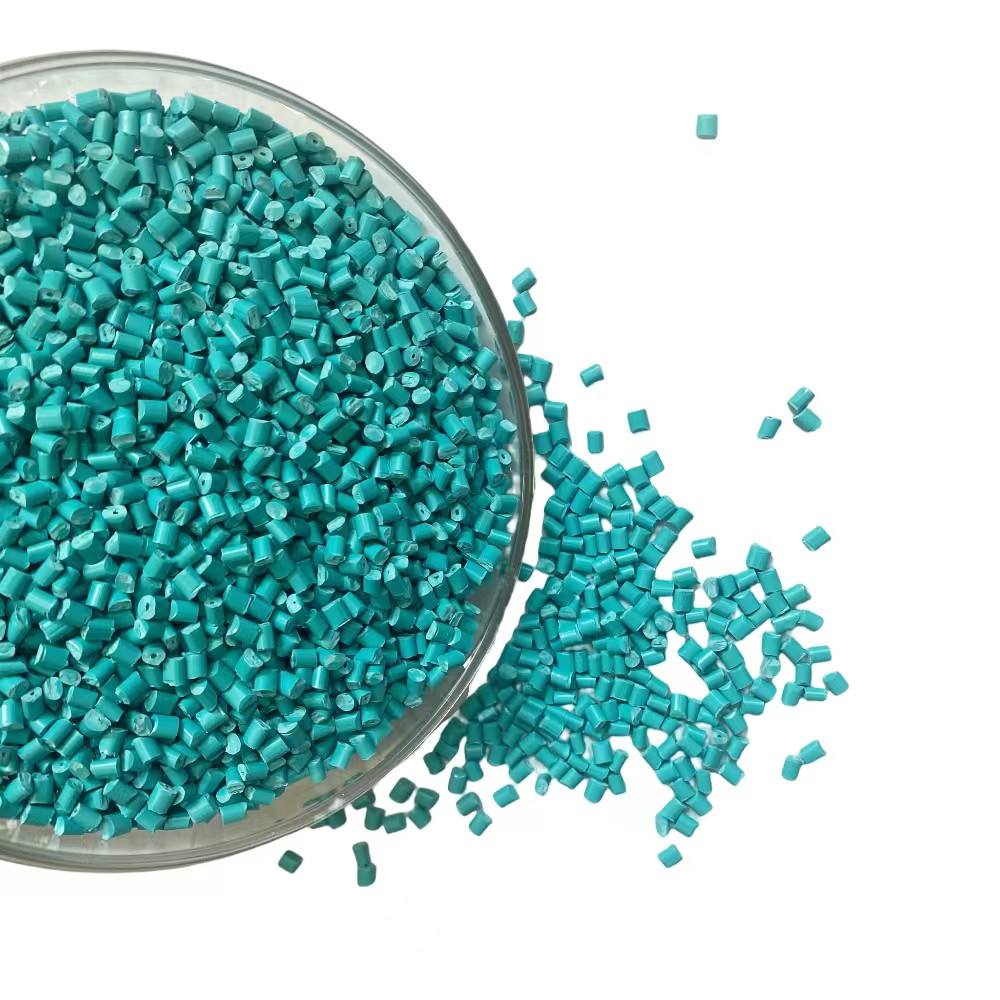

Additive Masterbatch is a type of plastic masterbatch that contains various additives to enhance the properties of plastic products. It is widely used in the plastic industry, especially for products that require high performance and specific characteristics. Our Additive Masterbatch is available in granule or pellet form and can be customized according to the specific needs of our customers.

Product Name: Additive Masterbatch

Our Additive Masterbatch is a pre-formulated masterbatch that contains a carrier and various additives to improve the performance and appearance of plastic products.

Carrier: PE/PP/ABS/PA/PVC/EVA/etc.

Our Additive Masterbatch is compatible with various types of plastic carriers, including PE, PP, ABS, PA, PVC, EVA, and more. This makes it suitable for a wide range of plastic products, from flexible packaging to rigid containers.

Carrier Content: 30%-70%

The carrier content in our Additive Masterbatch ranges from 30% to 70%, depending on the specific requirements of our customers. This ensures that the additives are evenly dispersed in the carrier, resulting in consistent performance and color in the final product.

Color: White/ Black/ Red/ Green/ Blue/ Yellow/ Etc.

Our Additive Masterbatch is available in a variety of colors, including white, black, red, green, blue, yellow, and more. We use high-quality pigments to ensure vibrant and consistent colors in the final product.

Shape: Granule/Pellet

Our Additive Masterbatch is available in granule or pellet form, making it easy to handle and add to the plastic manufacturing process. The shape and size of the masterbatch can be customized to suit the specific requirements of our customers.

Oxo-Biodegradable Masterbatch

Our Additive Masterbatch contains an Oxo-Biodegradable additive that makes the plastic products degrade faster when exposed to oxygen, sunlight, and heat. This helps reduce the environmental impact of plastic products and makes them more sustainable.

Customized Masterbatch

We understand that every plastic product has unique requirements, and one size does not fit all. That's why we offer customized Additive Masterbatch to our customers, tailored to their specific needs and applications. Our team of experts works closely with our customers to create a masterbatch that meets their desired characteristics, such as UV protection, flame retardancy, anti-static properties, etc.

Pre-Formulated Masterbatch

Our Additive Masterbatch is pre-formulated, which means it is ready to use and does not require any additional mixing or processing. This saves time and resources in the plastic manufacturing process, increasing efficiency and reducing costs.

In conclusion, our Additive Masterbatch is a high-quality and versatile solution for enhancing the performance and appearance of plastic products. With a wide range of carriers, colors, and customizable options, we can meet the unique needs of our customers and help them create sustainable and top-quality plastic products.

Features:

- Product Name: Additive Masterbatch

- Carrier: PE/PP/ABS/PA/PVC/EVA/etc.

- Melting Point: 90-160℃

- Density: 0.90-1.20g/cm3

- Shape: Granule/Pellet

- Compounded Masterbatch

- Blended Masterbatch

- Polymer Additives

Technical Parameters:

| Technical Parameter |

Value |

| Product Name |

Additive Masterbatch |

| Carrier Content |

30%-70% |

| Melting Point |

90-160℃ |

| Carrier |

PE/PP/ABS/PA/PVC/EVA/etc. |

| Density |

0.90-1.20g/cm3 |

| Color |

White/Black/Red/Green/Blue/Yellow/Etc. |

| Shape |

Granule/Pellet |

| Key Features |

Customized Masterbatch, Pre-Formulated Masterbatch |

Applications:

Brand Name: Chongyuan

Model Number: MBF000

Place of Origin: Xiamen, China

Certification: SGS

Minimum Order Quantity: 1 Set

Price: Negotiated

Packaging Details: 25Kg/Bag (paper-plastic package)

Delivery Time: 3-5 Days

Introducing Additive Masterbatch

Additive Masterbatch, also known as functional masterbatch, is a type of customized masterbatch that is used in various industries for improving the properties of plastic products. It is a blend of additives and carrier resin, which is added to the plastic during the manufacturing process to enhance its performance.

What Makes Additive Masterbatch Stand Out?

Additive Masterbatch is a popular choice for plastic manufacturers due to its numerous benefits. It not only improves the properties of plastic products but also reduces the production cost. Some of the key factors that make Additive Masterbatch stand out are:

- Customized Masterbatch: Additive Masterbatch can be customized according to the specific requirements of the plastic product, making it suitable for a wide range of applications.

- Blended Masterbatch: Additive Masterbatch is a blend of different additives, making it more convenient and cost-effective for manufacturers to use.

- High-Quality Additives: Chongyuan uses high-quality additives in our Additive Masterbatch, ensuring superior performance and durability of the plastic products.

- Wide Range of Additives: Our Additive Masterbatch is available in various types such as Antioxidant Masterbatch, UV Stabilizer Masterbatch, and Anti-static Masterbatch, allowing manufacturers to choose the one that best suits their needs.

The Applications of Additive Masterbatch

Additive Masterbatch has a wide range of applications in different industries. It is commonly used in the production of plastic products such as:

- Plastic Packaging: Additive Masterbatch is used to improve the strength, durability, and color of plastic packaging products, making them more suitable for storage and transportation.

- Automotive Components: The use of Additive Masterbatch in the manufacturing of automotive components makes them more resistant to UV rays, reducing the chances of discoloration and degradation.

- Building Materials: By adding Additive Masterbatch to plastic building materials, they become more weather-resistant, fire-resistant, and durable.

- Household Products: Additive Masterbatch is used in the production of various household products such as containers, toys, and furniture, making them more durable and aesthetically pleasing.

- Electronics: The use of Additive Masterbatch in the production of electronic components makes them more resistant to static electricity and UV rays, ensuring their longevity and performance.

Technical Specifications

Product Name: Additive Masterbatch

Melting Point: 90-160℃

Density: 0.90-1.20g/cm3

Color: White/ Black/ Red/ Green/ Blue/ Yellow/ Etc.

Shape: Granule/Pellet

Order Your Additive Masterbatch Today

Enhance the performance and appearance of your plastic products with Chongyuan's Additive Masterbatch. Our products are of high-quality, certified by SGS, and can be customized according to your specific requirements. Contact us now to place your order!

Customization:

Customized Service for Additive Masterbatch - Chongyuan

Brand Name: Chongyuan

Model Number: MBF000

Place of Origin: Xiamen, China

Certification: SGS

Minimum Order Quantity: 1 Set

Price: Negotiated

Packaging Details: 25Kg/Bag (paper-plastic package)

Delivery Time: 3-5 Days

Color: White/ Black/ Red/ Green/ Blue/ Yellow/ Etc.

Product Name: Additive Masterbatch

Shape: Granule/Pellet

Carrier Content: 30%-70%

Density: 0.90-1.20g/cm3

Chongyuan offers customized services for our Additive Masterbatch, also known as Blended Masterbatch, Customized Masterbatch, or Compounded Masterbatch. Our Additive Masterbatch is a highly effective and versatile product that can improve the quality and performance of plastic products.

Our Additive Masterbatch is available in various colors such as White, Black, Red, Green, Blue, Yellow, and more. We can also customize the color according to your specific requirements.

Our Additive Masterbatch comes in the form of granules or pellets, making it easy to mix and incorporate into your plastic products. The carrier content of our Additive Masterbatch ranges from 30% to 70%, depending on your needs. Our Additive Masterbatch also has a density of 0.90-1.20g/cm3, ensuring ease of use and compatibility with your plastic products.

With our Additive Masterbatch, you can enhance the properties of your plastic products, such as UV resistance, flame retardancy, anti-static performance, and more. Our team at Chongyuan is committed to providing high-quality and customized services to meet your unique requirements. Contact us now to discuss your Additive Masterbatch needs and get a competitive quote.

Packing and Shipping:

Additive Masterbatch Packaging and Shipping

The Additive Masterbatch is packaged in high-quality plastic bags to ensure its safety during transportation. The bags are then placed in sturdy cardboard boxes to prevent any damage during shipping.

The boxes are labeled with the product name, batch number, and storage instructions for easy identification and handling. Each box contains a specific number of bags, depending on the customer's order size.

For shipping, we use reliable and efficient logistics providers to deliver the Additive Masterbatch to our customers. The products are carefully loaded onto trucks or containers and secured for transportation.

Our team also conducts quality checks and inspections before shipping to ensure that the product meets our high standards and is in perfect condition.

Once the product reaches its destination, our packaging is designed to be easily opened and resealed for convenient storage and usage.

At Additive Masterbatch, we prioritize the safe and timely delivery of our products to our customers, ensuring their satisfaction and trust in our brand.