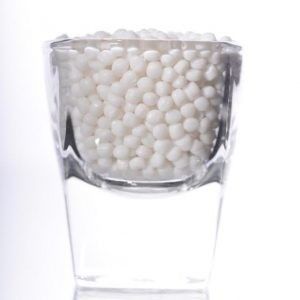

FILLER MASTERBATCH

CaCO3 filler masterbatch is kind of high dispersibility and stability of additive for polyolefin resin which protects machine's

precision. Reducing the cost of the finished product. Acid and alkali resistance, high temperature resistance, non-toxic and

tasteless.The product is a kind of particles that is refined on polyethylene as a carrier, with high quality calcium carbonate

powder and a variety of chemical additives . The mesh of calciumcarbonate is determined by the user's effect.It has a good

dispersion, stability.And there is no effect for the precision of the processing machine.In particular, it can reduce the cost of

incineration of environment-friendly plastic products.

.

lmprove heat resistance,rigidity and hardness.

Reduce molding shrinkage and improve dimensional stability.

Reduce burning heat and secondary pollution.

Can reduce the use of white masterbatch.

Improve the heat transfer perormance of plastics and shorten the molding cycle.

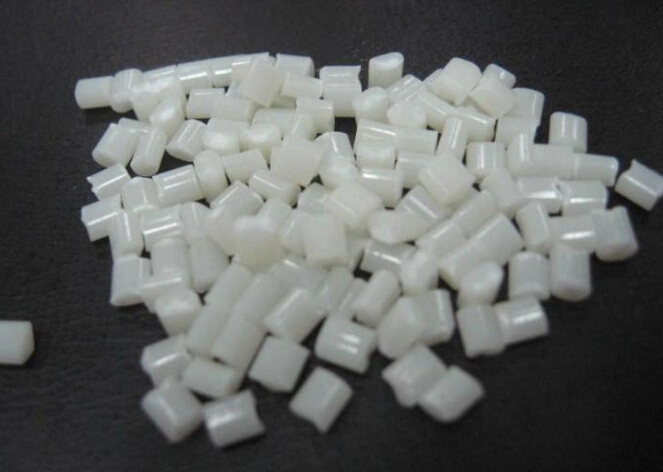

Resin: PE/PP

Filling ratio:70%-85%

Density:1.8-2.4g/cm³

Melting index (5KG/190℃):2-30g /10min

Company Profile

Chongyuan (Xiamen) Fine Chemical Co., Ltd. is a diversified enterprise specializing in the production and sales of color masterbatches, functional masterbatches, modified materials, as well as professional color matching and other customization. Founded in 1997, Chongyuan factory has always pursued superior product quality. With cutting-edge production equipment and a technical workforce with years of experience, Chongyuan maintains the products’ stability and consistency through strict quality control and fine management. And the products comply with EU RoHS directive, Sony Green Partner,and other environmental requirements.Furthermore, Chongyuan offers customers customized solutions and excellent after-sales services while using its core competitive advantages of technical strength, quality control, and customer service.

Our company utilizes the carbon master batch , which offers a comprehensive catalog of over 17,500 color recipes suitable for various polymers (including PE, PP, PET, PC, Styrene’s, Acrylics, Polyamides etc.).

We believe that through our combined expertise in these markets along with advanced manufacturing technology and unwavering commitment to innovation, we can expedite the development of solutions.

Environment Concern

- Persisting in the philosophy of “ Green chemical industry and environment concern”

- Energy Conservation and Pollution Emissions Reduction

- Passing RoHS/REACH/PAHs/DINP test,complying with EU RoHS directive, Sony Green Partner, and other environmental requirements

- With food grade safety standards - FDA, China national standard, European Union food contact plastic regulation certification (European (EC) No1935/2004(EU)No10/2011), does not contain bisphenol A, plasticizer and other limited substances

Capacity

Chongyuan Chemical has a workforce of over 1000 employees and operates five major production bases in China. The company has introduced nearly a hundred high-performance engineering plastic production lines, with an annual production capacity of 260,000 tons.The total number of masterbatch production lines is more than 60, of which the number of automatic production lines is as high as 4, and the efficient automatic production line can produce 288 tons of black and white masterbatches 24 hours a day, and the monthly production capacity is as high as more than 10,000 tons.

By importing advanced equipment such as high-speed, high-torque twin-screw extruders, automatic weighing, packaging, and stacking systems, Chongyuan Chemical has established an intelligent factory integrating intelligent equipment, IoT, MES, APS, and CMS. The company has implemented numerous advanced automated, digitalized,and intelligent production and testing equipment, providing a solid hardware foundation for the production of high-quality new materials.

The material will be packed in 25 Kg PP woven bags.

Customized packaging also can be done upon requirement.

Delivery Terms: - CIF, CFR, FOB

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!