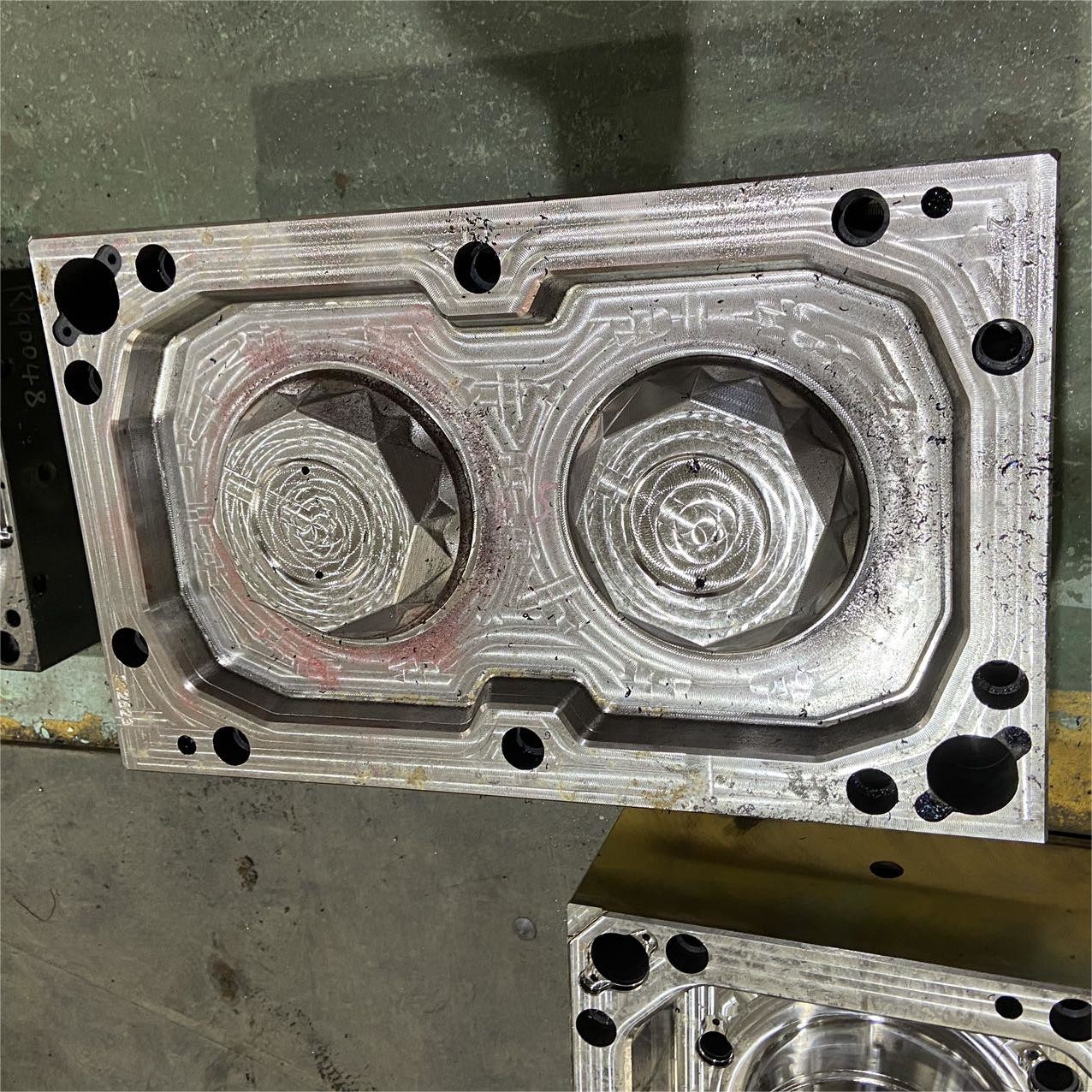

Precision Rotational Molds for Mass Production of High Quality Disposable Food Bowls & Containers

Product Description:

Chongyuan Fine Chemical is a one-stop shop for high-precision plastic injection molds. With our cutting-edge tooling solutions, customers can easily and cost-effectively manufacture volume plastic parts with precise specifications and features.

Our molds have the capability to produce the most complex plastic components. They are made to withstand the toughest manufacturing requirements, so customers can be sure of the performance of their plastic parts.

We are committed to consistently delivering the highest quality molds to meet the needs of our customers.

Features:

•Custom designs: Molds engineered specifically for customers' part geometries, styling needs and material specifications.

•Integrated ejection: Systems to efficiently remove plastic components from the mold after each cycle.

• Automated flashing: Technologies to effectively remove flash from molded plastic parts.

• Condition monitoring: Sensors and controllers to detect mold wear/damage for predictive maintenance.

•Process visualization: Real-time data on molding process parameters to identify and resolve issues quickly.

Technical Parameters:

| Mold Features |

Specification |

| Mold Standard |

HASCO, DME, etc. |

| Lead Time |

7-15 Days |

| Mold Life |

500,000-1,000,000 Shots |

| Mold Testing |

Water Pressure, Air Pressure, etc. |

| Mold Cooling |

Water Line, Fan, etc. |

| Surface Finish |

Polishing |

| Mold Ejection |

Ejector Pin, Stripper Plate, etc. |

| Design Software |

UG, ProE, CAD, etc. |

| Mold Gate |

Hot Tip, Submarine, etc. |

| Mold Base |

Steel |

Applications:

• Dinnerware & Lids

• Connectors, switches and controls for vehicles

• Housing parts for power tools and machinery

• Fan shrouds, diffusers and grilles for appliances

• Battery covers, side panels and frames for consumer electronics

• Surgical trays, instrument handles and device casings for healthcare

Customization:

Different clients require plastic components with diverse performance characteristics for their specific applications. At Chongyuan, we have the capabilities to precisely match customers' unique molding needs through customized injection molds optimized for their throughput, efficiency and quality targets. Our in-house engineers thoroughly review clients' part requirements, material choices and production parameters to develop plastic injection molds with exact specifications, features and specifications needed to produce plastic components according to manufacturers' exacting technical specifications in a cost-effective manner. This process optimization yields tailored molding solutions that reduce total part costs through minimizing material waste, maximizing yields and ensuring critical characteristics are met with each molding cycle.

Support and Services:

We provide technical support and services for our Plastic Injection Mold products. Our team of experienced engineers and technicians are available to provide technical assistance, troubleshooting, and repair services. With our extensive knowledge and experience in the field of plastic injection molding, we can help you achieve the best possible product quality and performance.

We offer comprehensive customer service and technical support for all our Plastic Injection Mold products. Our team of experts will provide assistance in the areas of product selection, installation, troubleshooting, and maintenance. We also offer customized solutions to suit your specific requirements.

We are committed to providing you with the highest level of service and support. Our team of experienced professionals is available to answer any questions you may have. We pride ourselves on providing our customers with the best possible service and support.

Packing and Shipping:

The plastic injection mold will be securely packaged for shipment. The mold will be carefully wrapped and protected with bubble wrap and/or other cushioning materials. It will then be placed in a heavy-duty cardboard box and sealed with tape. The box will be clearly labeled with the customer's name and address. The box will also be marked with "Fragile" and "Handle with Care" to ensure that it will be treated with care during shipping.

The box will be shipped by a reliable carrier such as UPS, FedEx, or DHL. The customer will be provided with tracking information so that they can monitor the shipment.

FAQ:

-

Q1. What makes your molds different?

A1. Our molds are engineered using the latest 3D CAD/CAM technologies for precision, optimal flow and balanced clamping forces. We offer mold coatings that extend tool life by 2-4x and reduce cycle times.

-

Q2. How long do your molds last?

A2. With proper care and maintenance, our molds can exceed 1 million cycles. Hardened steel alloys, durable coatings and robust components contribute to long service life.

-

-

Q3. What types of materials can your molds process?

A3.Our molds can produce parts in most types of engineering thermoplastics including ABS, PC, PA, PP and POM. We also support bioplastics and reinforced, filled and flame-retardant compounds.

-

Q4. How long does mold fabrication take?

A4. Standard molds take 6-12 weeks depending on part complexity, material requirements and automation needs. We can expedite some orders to 4 weeks or less.

-

Q5. What post-molding automation do you offer?

A5. We offer turnkey automation for trimming, ejection, stacking, quality inspection and packaging. Our integrated systems maximize part output while maintaining accurate part specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!