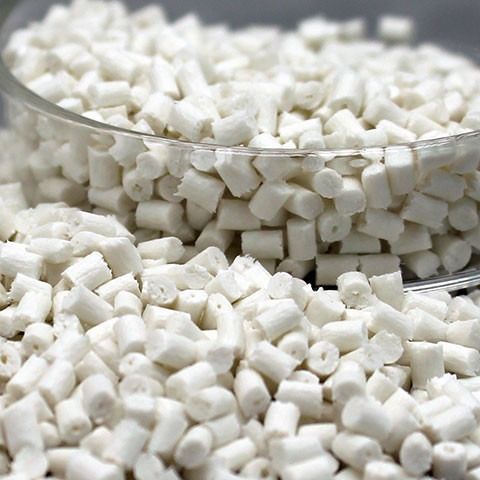

Versatile PA6 Engineering Resin With Low Water Absorption And Flexural Modulus 2.5 GPa

Product Description:

Chongyuan Fine Chemical provides a wide selection of polyamide 6 (PA6) plastic resins to fulfill the different needs of various manufacturing applications. Our PA6 raw materials are made of premium-quality virgin PA6 and is subjected to a careful production process to guarantee reliable quality and excellent performance.

Their superior properties such as heat resistance, hardness, impact strength and chemical resistance make our PA6 resins a great choice for injection molding and extrusion processes in fields like automotive, electronics, appliance and toy. In addition, PA6 raw material from us is completely compliant with international standards like RoHS and REACH. With their easy processability, customers can benefit from higher work efficiency.

We also have the capability to create customized PA6 grades to meet unique specifications according to customer's requirements. Our advanced technologies ensure the consistent quality and efficient production of our PA6 product line.

Features:

Our PA6 resins are excellent in terms of mechanical properties, providing high tensile strength, rigidity and hardness suitable for demanding load-bearing applications.

Moreover, they offer good impact resistance, maintaining flexibility and able to withstand impacts, making them durable for use in exterior parts. The materials also show superior heat resistance, having high softening/melting temperatures around 220°C and able to retain properties up to 80-90°C.

In addition, the raw materials offer exceptional chemical resistance, being resistant to a wide range of chemicals, greases and solvents. They also have low stress, avoiding warp during demolding, and process well on injection molding machines.

Furthermore, the materials are formulated to be UV resistant, preventing discoloration or degradation when exposed to the sun. And they are non-toxic, being food-contact compliant and containing no harmful/restricted substances.

On top of that, we offer customization support, being able to develop materials with tailored properties like heat/flame resistance, lubricity or toughened impact strength. And, with rigorous quality control, we ensure the consistently high quality and uniform product specs and color across batches.

Finally, all our PA6 grades are manufactured meeting RoHS, REACH and other international standards.

Technical Parameters:

Aliphatic polyamide is a chemical structure, which is in a form of semicrystalline granules. It has a density of 1.14 g/cm3 and a melting point of 220°C. Its softening point is 80°C and water absorption is 5%. Additionally, its moisture content is ≤0.1%, with a molecular weight ranging from 20000-30000.

In terms of strength, tensile strength is ≥55 MPa, tensile modulus is ≥2500 MPa, elongation at break is ≥50%, flexural strength is ≥80 MPa, flexural modulus is ≥2500 MPa, and hardness in Rockwell R scale is ≥105. Izod impact strength for this chemical structure is ≥10 kJ/m2, with a thermal index of ≥80°C. When processing, the temperature should be 210-240°C and its moisture content should be ≤0.04%.

Applications:

Polyamide 6 (PA6) plastic raw materials is a multi-Spurpose material with a wide range of applications. In the automotive industry, it is utilized for under-bonnet components, intake manifolds, air ducts, oil pans, cargo liners, seat components, electrical connectors and more. In electrical and electronics production, PA6 is widely used for connectors, switches, casings, plugs, relay housings and other parts. It is also common in the household appliance industry for manufacturing washing machine parts, dryer parts, vacuum cleaner parts and iron parts.

Moreover, polyamide 6 is used in consumer goods such as toothbrush handles, power tool casings, water bottles and sporting goods, as well as in industrial equipment including machine components, pump housings, tubing and conveyor parts. Thin wall packaging from PA6 provides an excellent price to performance balance for food containers, detergent bottles, cosmetic jars and more. In health-related technologies, PA6 is often employed for prosthetics, dental appliances and surgical instruments, and in fibres and textiles due to its abrasion resistance. Lastly, the material is used as a 3D printing filament in FDM 3D printing for prototyping.

Our PA6 grades offer an unbeatable combination of mechanical strength, rigidity, toughness and heat resistance. If you have a project that involves PA6, please reach out to us and we'll be happy to provide you with a custom solution that is tailored to enhance your manufacturing operations and end products.

Customization:

Customized Engineering Plastics

Chongyuan provides customized engineering plastics, including engineering composite, engineering copolymer and engineering polymer. Our product model is PA6400. All of our products with RoHS, ISO, REACH certification and meet the minimum order quantity of 1kg.

The flexural modulus of engineering plastics is 2.5 GPa, and the elongation at break is Min.80%. The impact strength is 20 KJ/m2, and the thermal conductivity is 0.2 W/mK. The MFR of engineering plastics is 10-20 G/10min.

The price of engineering plastics can be negotiated. The packaging details are 25kg/bag. The delivery time is 5-8 workdays and the payment terms are L/C, T/T, D/P, Western Union. The supply ability of our product is 100,000 tons/month.

Support and Services:

Engineering Plastics Technical Support and Service

We provide technical support and service for all our engineering plastics products to ensure you can get the best usage out of them. Our team of experts is available to help with any questions or issues you may have regarding your engineering plastics.

We provide a range of support options, including:

- Guidance on selecting the most suitable engineering plastic for your application

- Advice on installation and maintenance

- Technical documentation

- Troubleshooting and repair services

- On-site support

If you have any questions or require any assistance, please don’t hesitate to contact us.

Packing and Shipping:

Engineering Plastics should be well packaged and shipped to ensure its safety and integrity.

Packaging:

- Engineering Plastics should be packed in an airtight plastic bag, and then placed in a cardboard box.

- The bag and box should be clearly labeled with the product name, weight, and quantity.

- The box should also include a list of contents and any other relevant information.

- The box should be secure enough to prevent any damage during shipment.

Shipping:

- Engineering Plastics should be shipped via a reliable courier service.

- The packaging and shipping should be done in a timely manner.

- Insurance should be taken out to ensure that any loss or damage is covered.

- Tracking information should be provided to the customer.

FAQ:

- Q:What is Engineering Plastics?

- A:Engineering plastics are a group of plastic materials that have better mechanical and/or thermal properties than the more widely used commodity plastics (such as polystyrene, polyethylene, PVC, etc.).

- Q:What is the brand name and model number of Engineering Plastics?

- A:The brand name is Chongyuan and the model number is PA6400.

- Q:Where is Engineering Plastics from?

- A:Engineering Plastics is from China.

- Q:What certifications does Engineering Plastics have?

- A:Engineering Plastics has RoHS, ISO, and REACH certifications.

- Q:What is the minimum order quantity and price of Engineering Plastics?

- A:The minimum order quantity is 1kg and the price is negotiable.

- Q:How is Engineering Plastics packaged and how long is the delivery time?

- A:Engineering Plastics is packaged in 25kg/bag and the delivery time is 5-8 workdays.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!