Product Description:

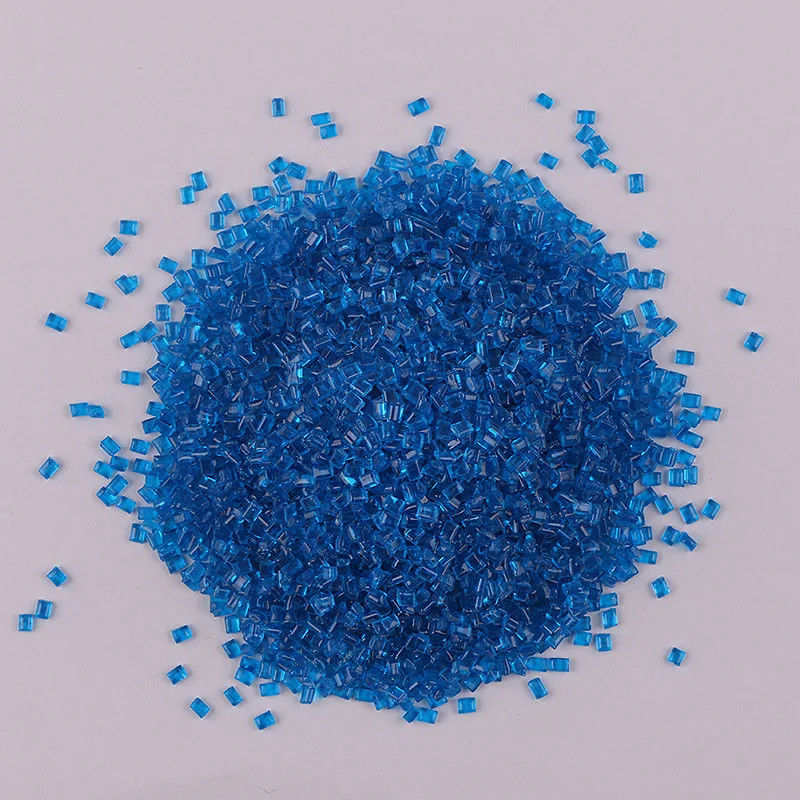

Chongyuan's PA-800 resins provide a reliable and economical engineering thermoplastic compounds solution for demanding applications. These polyamide 66 based resins offer high performance and excellent properties, including strength, rigidity, toughness and heat resistance. These resins are perfect for applications that require precision parts that can withstand elevated temperatures.

In addition, these advanced resins are cost-effective, meaning they can be used for a variety of applications from automotive components to electrical parts. Their ability to perform in demanding applications even at high temperatures has made them the preferred choice for many industries.

Features:

Our products possess excellent mechanical properties, making them highly suitable for a variety of applications. The high heat deflection temperature of up to 150°C makes them long-lasting and durable even at high temperature. Moreover, they have excellent chemical resistance to solvents and weathering, enabling them to work in difficult environment.

In addition, our products have been specially designed to provide an easy processing experience on injection/compression molding machines, resulting in an efficient production. The superior finishing and smooth surfaces make them aesthetically-pleasing while the non-toxic and food contact compliant nature ensures complete safety.

Technical Parameters:

| Property |

Value |

| Flexural Modulus |

≥ 2800 MPa |

| MFR |

2-7 G/10min |

| Flexural Strength |

≥ 110 MPa |

| Density |

1.13-1.14 G/cm3 |

| Moisture Content |

≤ 0.1% |

| Tensile Strength |

Min. 60MPa |

| Impact Strength |

≥ 20 KJ/m2 |

| Material |

Polycarbonate |

| Heat Deflection Temperature |

≥ 150°C |

| Engineering Polymer Blend |

Yes |

| Engineering Polymer Alloy |

Yes |

| Engineering Composite |

Yes |

Applications:

When it comes to electrical and electronic components, our team is always ready to provide reliable solutions. Our company has been specialized in the design and production of components for over 15 years.

We have extensive experience in producing automotive engine parts, industrial equipment housings, consumer goods and appliances, sanitary and medical equipment, and precision parts that require dimensional stability. We boast a highly experienced team of professionals who have worked in the industry for many years.

Our commitment to quality and customer service is second to none. We strive to provide our customers with the highest quality products at competitive prices. We provide top-notch services to ensure that all our products arrive in perfect condition and meet the highest standards.

Our experienced team is dedicated to providing you with the best quality products for your needs. Whether you need components for a large-scale project or just a few pieces for repairs, we guarantee fast and efficient service.

Customization:

We provide quality engineering plastics from Chongyuan with the model number PC-800. It is manufactured in China and is certified with RoHS, ISO, and REACH. It is available in a minimum order quantity of 1kg and the price is negotiable. It is packaged in 25kg/bag and the delivery time is 5-8 workdays. We accept payment terms such as L/C, T/T, D/P, and Western Union. Our engineering copolymer, engineering polymer matrix, and engineering thermoplastic have a supply ability of 100,000 tons/month and a density of 1.13-1.14 G/cm3 with a moisture content of ≤0.1%. The flexural modulus is ≥2800 MPa and the flexural strength is ≥110 MPa. The tensile strength is a minimum of 60 MPa.

Packing and Shipping:

Packaging and Shipping of Engineering Plastics

Engineering plastics are light weight, easy to process, and have a wide range of uses. They can be used in a variety of industries and applications. As such, it is important to ensure that the engineering plastics are packaged and shipped correctly to ensure their quality and performance.

Packaging

Engineering plastics should be packaged in a manner that prevents damage during shipment. This includes using appropriate boxes or containers for the product and packing the product securely to reduce the risk of damage. The product should also be clearly labeled with the type of plastic, size, and any other relevant information.

Shipping

Engineering plastics should be shipped using a reliable carrier. The shipping carrier should have a good track record for delivering packages safely and on time. The package should be properly labeled with the destination address and any other relevant information. It is also important to track the shipment to ensure that it arrives at its destination on time.

FAQ:

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!