Product Description:

Chongyuan offers high performance polyamide-66-based engineering thermoplastic compounds with their PA-800 resins. Perfect for precision parts, these compounds bring together strength, rigidity, and toughness with an added bonus of heat resistance for those applications that demand it.

The PA-800 has proven its worth in a wide variety of industries and continues to be a reliable choice for many applications.

Features:

Polyoxymethylene (POM) demonstrates excellent mechanical properties that can easily be processed on injection and compression molding machines. This material is renowned for its smooth surfaces and superior finishing abilities, as well as providing a high heat deflection temperature up to 150°C. What's more, it is also resistant to weathering and solvents, making it perfect for outdoor applications. Additionally, it is non-toxic and food contact compliant, which makes it suitable for food contact applications or where safety is paramount.

In conclusion, POM is an ideal engineering material that provides numerous advantageous properties, such as its excellent mechanical properties, ease of processing and superior finishing. Additionally, its high heat deflection temperature, combined with its resistance to weathering and solvents, makes it perfect for outdoor applications. Finally, its non-toxic composition and food contact compliance make it perfect for use in food contact applications or applications where safety is of an utmost importance.

Technical Parameters:

| Property |

Value |

| Heat Deflection Temperature |

≥150°C |

| Flexural Modulus |

≥2800 MPa |

| Material |

Polycarbonate |

| MFR |

2-7 G/10min |

| Flexural Strength |

≥110 MPa |

| Density |

1.13-1.14 G/cm3 |

| Tensile Strength |

Min. 60MPa |

| Impact Strength |

≥20 KJ/m2 |

| Moisture content |

≤0.1% |

Applications:

We offer various products used in a variety of industries, including electrical and electronic components, automotive engine parts, industrial equipment housings, consumer goods and appliances, sanitary and medical equipment, and precision parts requiring dimensional stability.

Our components are used in many different types of applications and industries. We specialize in manufacturing precision engineered components that maintain dimensional stability and stringent quality standards. We also provide custom-designed parts for specialized projects.

Our experience in the industry combined with our state-of-the-art manufacturing technology enables us to create reliable, high-performing components that meet the unique needs of each customer.

To ensure high-quality products, we employ a strict quality control system, working with our staff and suppliers to ensure each product is of the highest quality. We have the capability to manufacture and deliver large orders quickly and accurately with minimal environmental impact.

Customization:

Customized Engineering Plastics Service

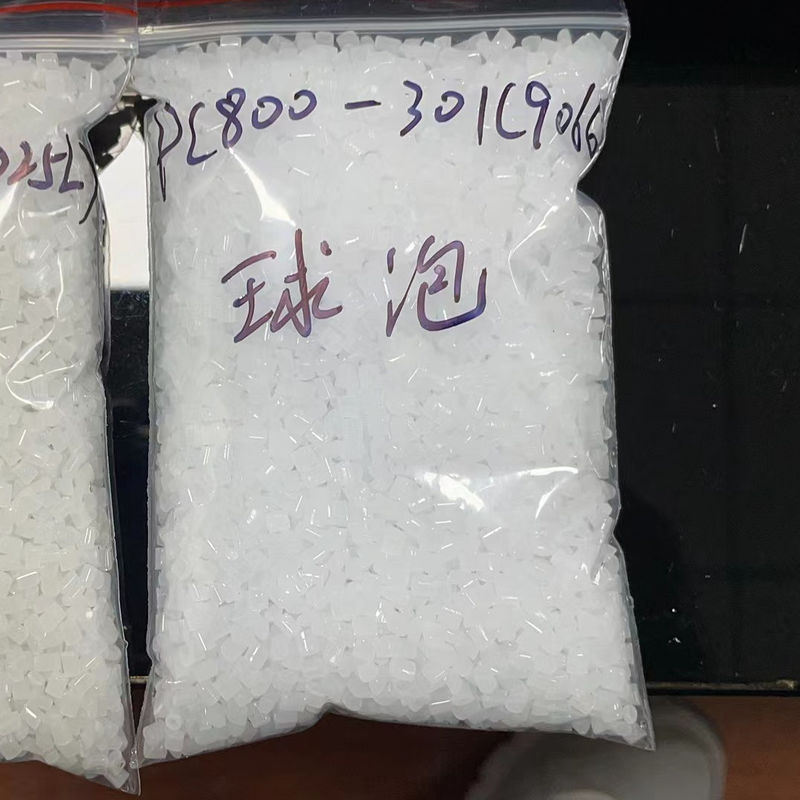

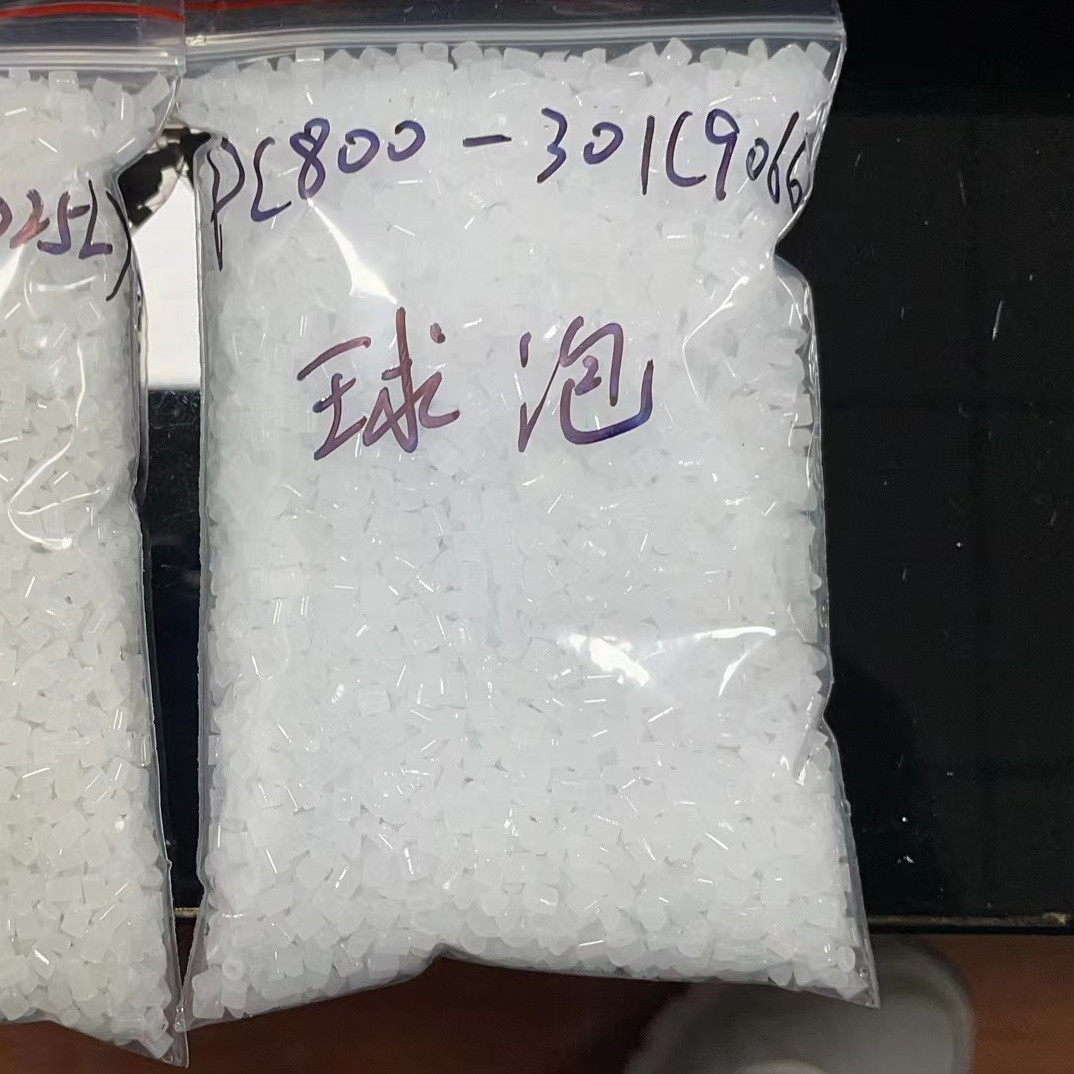

Chongyuan offers custom-engineered engineering plastics to fit all your needs. Our engineering plastics are made with the highest quality materials and are available in a wide variety of models, such as PC-800. All of our engineering plastics are RoHS, ISO, and REACH certified. We offer a minimum order quantity of 1kg and pricing is negotiable. Our engineering plastics are packaged in 25kg/bag and delivery time is 5-8 working days. We accept payment through L/C, T/T, D/P, and Western Union. Our supply ability is 100,000 tons/month and our MFR is 2-7 G/10min. Some of the features of our engineering plastics include a heat deflection temperature of ≥150°C, a moisture content of ≤0.1%, a tensile strength of min. 60MPa, and a density of 1.13-1.14 G/cm3.

Packing and Shipping:

Engineering Plastics are typically packaged in a variety of materials such as bubble wrap, foam, cardboard, and shrink wrap. The packaging should be designed to protect the product from damage during shipping and handling. Shipping is typically done via truck, rail, air, or sea, depending on the weight and size of the product and the destination. For large orders, it is often more cost-effective to ship via a freight carrier. For smaller orders, parcel delivery services such as UPS, FedEx, and USPS are typically used.

FAQ:

Q1: What is Engineering Plastics?

A1: Engineering Plastics is a type of thermoplastic polymer created from petroleum and used in a wide range of products and applications. It is strong, lightweight and usually has high heat resistance.

Q2: What is the Brand Name of Engineering Plastics?

A2: The Brand Name of Engineering Plastics is Chongyuan.

Q3: What is the Model Number of Engineering Plastics?

A3: The Model Number of Engineering Plastics is PC-800.

Q4: Where is Engineering Plastics made?

A4: Engineering Plastics is made in China.

Q5: What certifications does Engineering Plastics have?

A5: Engineering Plastics has RoHS, ISO, REACH certifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!