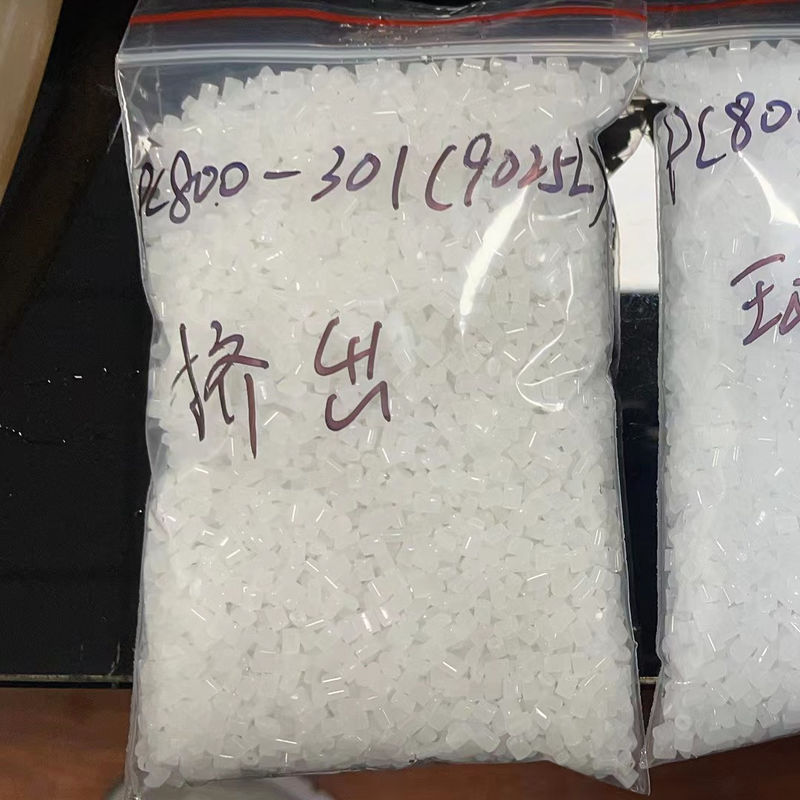

Product Description:

Chongyuan's PA-800 resins are an excellent choice for precision parts fabrication due to their unplasticized polyamide 66 engineering thermoplastic compound formula. This combination of strength and rigidity with improved heat resistance makes them suitable for demanding applications, unlike traditional plastic materials.

The PA-800 resin has many superior qualities compared to traditional plastics. It has improved hardness, better abrasion resistance and fatigue durability than other polyamides. Additionally, it has excellent heat distortion resistance and higher dimensional stability.

This makes PA-800 resin a great choice for injection molding applications. Its superior strength-to-weight ratio is ideal for parts which require durability but must remain lightweight. It produces high-quality parts with minimal warpage and superior surface finish.

Features:

Polypropylene is a sturdy plastic material with excellent mechanical properties, with the heat deflection temperature can reach as high as 150°C, also resistant to many solvents and able to stand exposure in bad weather conditions.

It is simple to process on injection/compression molding machines and can provide superior finishing and smooth surface.

Moreover, this material is non-toxic and can be used in food contact without any worry.

Technical Parameters:

| Property |

Value |

| Material |

Polycarbonate |

| Heat Deflection Temperature |

≥150°C |

| Flexural Modulus |

≥2800 MPa |

| Flexural Strength |

≥110 MPa |

| MFR |

2-7 G/10min |

| Moisture Content |

≤0.1% |

| Tensile Strength |

Min. 60MPa |

| Impact Strength |

≥20 KJ/m2 |

| Density |

1.13-1.14 G/cm3 |

| Engineering Reinforced Plastic |

Yes |

| Engineering Elastomer |

Yes |

| Engineering Polymer Matrix Composite |

Yes |

Applications:

As a manufacturer, we specialize in a wide range of products and services including:

- Electrical and Electronic components

- Automotive engine parts

- Industrial equipment housings

- Consumer goods and appliances

- Sanitary and medical equipment

- Precision parts requiring dimensional stability

Manufacturing products for various industries, we strive to provide quality parts and services with most orders completed within 7 working days.

Customization:

We offer custom services for Engineering Plastics with the following attributes:

- Brand Name: Chongyuan

- Model Number: PC-800

- Place of Origin: China

- Certification: RoHS, ISO, REACH

- Minimum Order Quantity: 1kg

- Price: can be negotiated

- Packaging Details: 25kg/bag

- Delivery Time: 5-8 workdays

- Payment Terms: L/C,T/T,D/P,Western Union

- Supply Ability: 100,000 tons/month

- Material: Polycarbonate

- Heat Deflection Temperature: ≥150°C

- Moisture content: ≤0.1%

- MFR: 2-7 G/10min

- Flexural Modulus: ≥2800 MPa

We specialize in Engineering Copolymer, Engineering Elastomer, Engineering Reinforced Plastic and Polycarbonate.

Packing and Shipping:

Packaging and Shipping for Engineering Plastics:

- Engineering plastics should be stored in a clean, dry, and well-ventilated area.

- They should be protected from moisture, dust, and other contaminants.

- The packaging should be able to protect the engineering plastics from damage and contamination during shipping and storage.

- The packaging should be designed to prevent any leakage of the engineering plastics.

- The packaging should be labeled with the appropriate product information.

- The packaging should be properly sealed to ensure that it is secure and tamper-proof.

- The shipping method should be chosen based on the type of engineering plastics and its intended use.

- The shipping container should be properly secured and labeled.

FAQ:

- Q: What is Engineering Plastics?

- A: Engineering plastics are plastic materials that have special physical and chemical properties, and are suitable for use in engineering and industrial applications.

- Q: What is the Brand Name and Model Number of Engineering Plastics?

- A: The Brand Name is Chongyuan and the Model Number is PC-800.

- Q: Where is Engineering Plastics made?

- A: Engineering Plastics is made in China.

- Q: What certifications does Engineering Plastics have?

- A: Engineering Plastics has RoHS, ISO, REACH certifications.

- Q: What is the minimum order quantity for Engineering Plastics?

- A: The minimum order quantity for Engineering Plastics is 1kg.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!