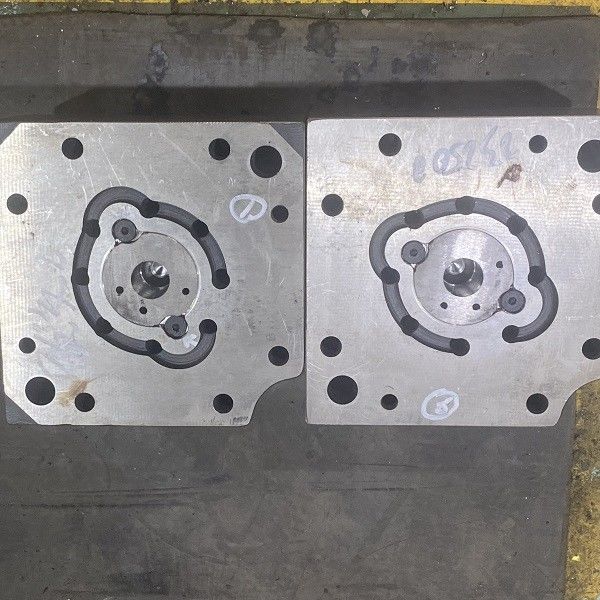

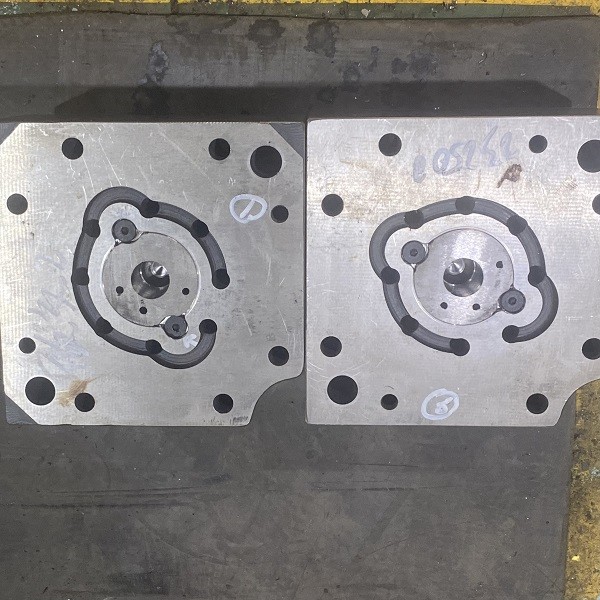

Customized Single Or Multi Cavity Injection Molded Parts With Smooth Or Textured Surface Finish

Product Description:

Plastic Injection Mold is a type of industrial process for producing injection molded parts and components from thermoplastic and thermosetting plastic materials. It is capable of producing complex shapes with high accuracy and repeatability, and is widely used in the manufacturing of a variety of parts and components for a variety of industries. The injection molding process involves the injection of plastic resin into a pre-made mold insert, usually made from steel or aluminum, with a single or multi-cavity mold cavity. The plastic is then heated and injected into the mold cavity, which is then cooled to form the desired part or component. The mold base is typically made from aluminum or steel, and the mold weight can be customized to meet the needs of the customer. Injection molded plastics can provide a variety of benefits including improved strength, durability, and cost-efficiency for a wide range of applications. Thermoset injection molding is another type of injection molding process used to produce parts and components from thermosetting plastic materials. This type of injection molding process is often used for the production of parts requiring complex shapes, as well as those requiring high levels of strength and durability.

Features:

- Product Name: Plastic Injection Mold

- Mold Precision: ±0.001mm

- Mold Cooling System: Water Or Oil

- Mold Core: Steel Or Aluminum

- Mold Weight: Customized

- Mold Price: Customized

- Injection Molded Components: Precision and Accuracy

- Plastic Injection Molding: Durability and Reliability

- Injection Molded Plastics: Cost-Effective Solutions

Technical Parameters:

| Parameters |

Values |

| Mold Core |

Steel Or Aluminum |

| Mold Type |

Injection Mold/Thermoplastic Molding/Thermoplastic Injection/Thermoset Injection Molding |

| Mold Cavity |

Single Or Multi |

| Mold Surface Finish |

Smooth Or Textured |

| Mold Cooling System |

Water Or Oil |

| Mold Precision |

±0.001mm |

| Mold Ejection System |

Manual Or Automatic |

| Mold Base |

Aluminum Or Steel |

| Mold Lead Time |

2-4 Weeks |

| Mold Inserts |

Steel Or Aluminum |

Applications:

Chongyuan's injection molding technology is the ideal choice for most thermoplastic and thermoset injection molded plastic parts. Our Custom Injection Molded Parts are produced with the highest quality raw materials and with precise attention to detail. Our injection molds are designed and manufactured with the most modern techniques, ensuring the highest quality and most affordable price. With our Injection Molded Plastics you can be sure that your parts will last and have the best performance. Our Model Number M000 is made from high-quality plastic and has a smooth or textured surface finish to meet your requirements. The price is negotiable depending on the size and complexity of the part and the Mold Price is customized for each project. We also provide a variety of Mold Cooling Systems, including water or oil, to ensure that your part is properly cooled and has the right weight. Our Thermoplastic Injection and Thermoset Injection Molding technology provides the perfect solution for your project. With Chongyuan's injection molding technology, you get a product that is reliable, cost-effective, and long-lasting.

FAQ:

Q1: What is Plastic Injection Mold?

A1: Plastic Injection Mold is a tool for producing plastic parts in large volume with high precision. It is produced by injecting molten plastic material at high pressure into a mold cavity, which is the inverse of the desired shape.

Q2: What is the Brand Name of Plastic Injection Mold?

A2: The Brand Name of the Plastic Injection Mold is Chongyuan.

Q3: What is the Model Number of Plastic Injection Mold?

A3: The Model Number of the Plastic Injection Mold is M000.

Q4: Where is the Place of Origin of Plastic Injection Mold?

A4: The Place of Origin of the Plastic Injection Mold is Xiamen, China.

Q5: What is the Price of Plastic Injection Mold?

A5: The Price of the Plastic Injection Mold is Negotiated.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!